In water-based personal care products—such as water flossers, facial steamers, or humidifiers—tank mold has emerged as a silent threat. When left unaddressed, it not only affects product hygiene but can also trigger bacterial regrowth, potentially turning an everyday device into a long-term health risk. In this blog, we explore the relationship between tank design, mold formation, and microbial resurgence, and explain how manufacturers can prevent these issues through engineering and process control.

Tank mold typically forms in water reservoirs that are enclosed, hard to clean, or exposed to warm, humid conditions. When users refill tanks without thorough drying or cleaning, residual moisture creates an ideal breeding ground for microbial colonies. Over time, the humid interior, combined with organic residues (like saliva, essential oils, or skin cells), facilitates fungal growth—especially on porous or improperly sealed surfaces. Once this mold appears, it not only produces unpleasant odors but also begins releasing spores into the water system.

While mold is visible and easier to detect, bacterial regrowth is the more dangerous counterpart. When a device’s internal water pathway is contaminated, certain bacteria—such as Pseudomonas aeruginosa or Streptococcus—can regrow after incomplete cleaning or exposure to residual moisture. The problem worsens when:

This regrowth can expose users to pathogenic bacteria every time they turn on the device—making it more than just a cosmetic concern. Company web: https://www.powsmart.com/product/electric-toothbrush/

When bacterial regrowth originates from tank mold, it may lead to:

As such, mold- and bacteria-contaminated tanks are not merely an aesthetic defect—they represent a potential public health hazard if scaled across production batches.

.jpg)

.jpg)

Manufacturers must understand that tank-related microbial issues often begin at the design level. Contributing factors include:

Addressing these pain points early in product design can drastically reduce long-term contamination risks.

To prevent bacterial regrowth and eliminate tank mold, manufacturers can implement the following:

By engineering for hygiene at the source, brands can protect both their users and their reputation.

In an increasingly hygiene-conscious market, manufacturers should proactively position themselves as safety leaders by:

This not only addresses immediate product safety but also builds a defensible market position for professional buyers and distributors.

Tank mold and resulting bacterial regrowth aren’t just surface-level flaws—they represent deeper system design and materials challenges that, if ignored, can escalate into serious health concerns. By rethinking reservoir design, choosing hygienic materials, and embedding smart sterilization solutions, B2B manufacturers can prevent microbial outbreaks before they occur. In the post-pandemic era of heightened consumer health awareness, clean design isn’t optional—it’s your competitive edge. Contact us

Orthodontic Electric Toothbrush for Braces – Deep Cleaning Bristle Design

.jpg)

Montgomery Wellness Products Vendor | Corporate Oral Care Gifts

Does Gum Massage Mode Truly Boost the Receding Gums Solution Effectiveness?

.jpg)

Is Your Whitening Inefficiency Caused by Low-Quality Teeth Whitener Nano Coating?

Top 10 California electric toothbrush factory for OEM/ODM Services

Black & White Smart Toothbrushes: Minimalist Design for Bulk Orders

How Can a Smart Timer Chip Feature Be Highlighted Through Packaging Customization Service?

How Long Will It Take to See Results with the LED Teeth Whitening Device?

.jpg)

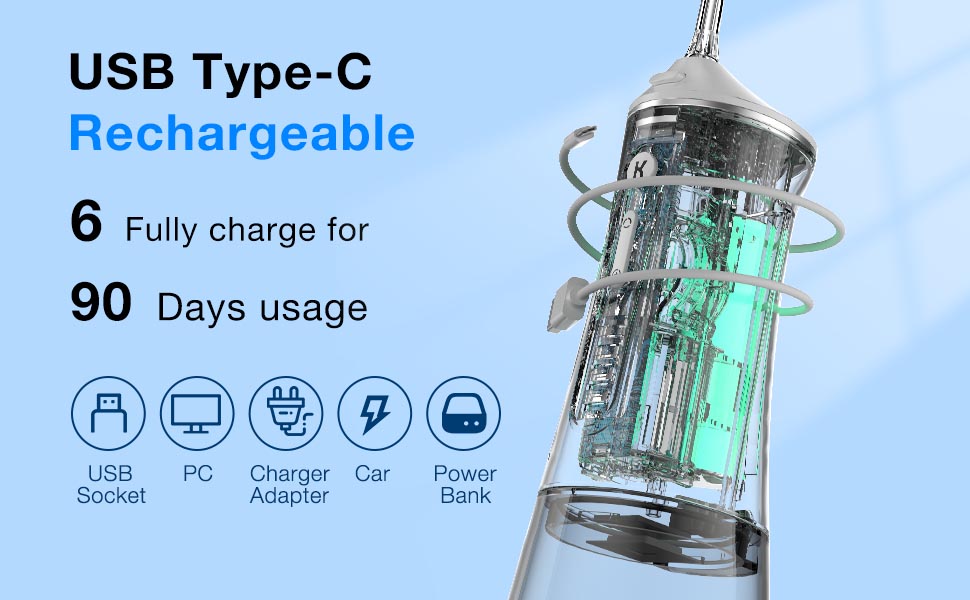

USB-C Water Flosser Wholesale | Fast-Charging Oral Irrigator Distributor

.jpg)

Mode Glitches During Calibration Drift – What’s Really Happening?

.jpg)

Electric Toothbrush Warranty Policy for OEM & Private Label Brands

.jpg)

Teeth Stain Removal Enamel Protection: Remove Stains Safely

Can sensitive toothpaste reverse gum recession?

What Causes the Intermittent Water Flow When Using an Oral Irrigator?

.jpg)

Natural Teeth Whitening Methods That Work

.jpg)

Bulk Kids Electric Toothbrush Supplier Tacoma Schools | Affordable Oral Care