In professional and consumer whitening devices alike, whitening rebound—the rapid re-staining of teeth after treatment—remains a frustrating concern. Increasingly, technical analysis reveals a link between light decay in LED systems and premature loss of whitening results. Is whitening rebound after light decay inevitable, or can manufacturers mitigate this hidden flaw? Let’s examine the critical factors.

Whitening rebound refers to the gradual reversal of tooth whitening, often within weeks of treatment. Common causes include:

For brands, whitening rebound undermines product promises and reduces customer satisfaction.

Light decay in LED-based whitening devices refers to:

As whitening relies heavily on photo-activation, light decay directly reduces gel activation efficiency—making even high-quality gels less effective. Company web:https://www.powsmart.com/product/electric-toothbrush/

Light decay and whitening rebound are closely linked via:

Thus, unnoticed light decay silently undermines whitening results, pushing users toward premature rebound.

Light decay often results from avoidable design and process flaws:

These oversights compromise the consistency of light output and overall device performance.

To combat whitening rebound caused by light decay, manufacturers should:

These measures ensure stable, consistent light energy delivery across the device’s usable life.

Solving light decay and subsequent translates into:

By addressing the root cause—light decay—manufacturers safeguard product reputation and drive market differentiation.

Is whitening rebound after light decay inevitable? Not if manufacturers prioritize LED stability and optical performance. By recognizing the impact of light decay on gel activation and whitening results, and implementing robust design safeguards, brands can offer lasting, professional-grade whitening solutions that retain customer trust.Contact us

.jpg)

.jpg)

How to Prevent Water from Enter the Handle of an Electric Toothbrush?

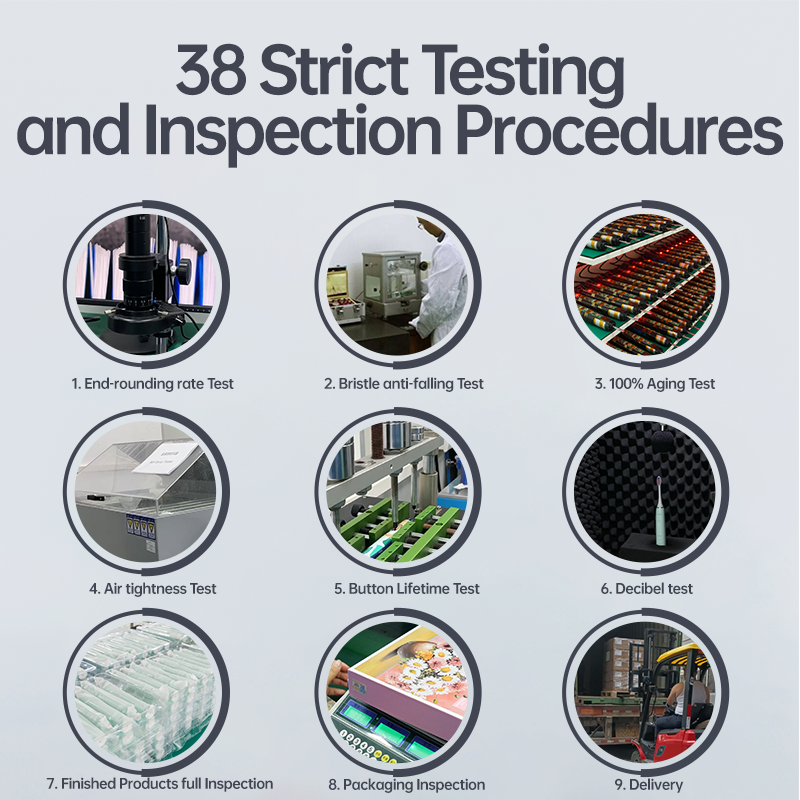

Unveiling the production of electric toothbrushes

.jpg)

Wholesale Smart Electric Toothbrush Factory | Bulk Supplier

.jpg)

Professional Dental Water Flosser Supplier

.jpg)

Corporate Gift Electric Toothbrush Wholesale

Can Minimizing Chromatic Aberration Increase Luminescence Efficiency in Whitening Devices?

Does Clinical Gum Mode Really Work?

Don’t Fall for These Viral Teeth Whitening Trends: Dentist-Approved whitening

How Wireless Tech is Revolutionizing Oral Care Devices

How to Deal with the Electric Toothbrush That Automatically Starts Up?

.jpg)

Why Post-Whitening Diets Need Gum Inflammation Cautions?

.jpg)

Why Is an Auto Shutdown Feature Essential for Battery Powered Oral Care Devices?

.jpg)

Are You Brushing Too Hard?

.jpg)

Planning Bulk Orders for a Smart Toothbrush OEM Product?

Comparison of Electric Toothbrush Battery Types: How to Choose the Power Solution That Best Suits Your Brand Positioning?

.jpg)

Portable Electric Toothbrush for College Hostel Life