In today’s competitive manufacturing landscape, ensuring the operational reliability of industrial equipment and consumer devices is paramount. However, challenges such as Temperature Spikes and Handle Slippage can disrupt performance and compromise user safety. When components experience sudden thermal fluctuations, they often expand and contract, potentially weakening grip mechanisms and leading to unexpected slippage during operation. In this blog, we explore the root causes of these issues and provide actionable strategies to mitigate them.

Effective system performance relies on both proper thermal management and secure physical interfaces. Temperature Spikes—rapid increases in operating temperature—can alter material properties and adversely affect components. Simultaneously, Handle Slippage occurs when the gripping mechanism fails to hold securely, often due to material degradation or changes in dimensions triggered by heat. Understanding these challenges is the first step in developing robust design and maintenance strategies.

Temperature spikes can be caused by various factors such as inefficient cooling, unexpected power surges, or environmental fluctuations. When a component experiences a sudden rise in temperature, it may lead to:

These effects highlight the importance of stabilizing operational temperatures to preserve component integrity and performance.

Handle Slippage occurs when the grip on a device or tool becomes less effective, posing safety risks and reducing control precision. Key factors contributing to handle slippage include:

Addressing handle slippage requires a combined focus on materials, design, and maintenance practices.

Company Web: https://www.powsmart.com/product/electric-toothbrush/. Contact us if you want to more information.

The correlation between Temperature Spikes and Handle Slippage is often more than coincidental. When a device heats up excessively, even briefly, the resulting thermal expansion can disrupt the microscopic textures that secure a proper grip. Over time, this repeated stress can lead to permanent changes in the handle material, accelerating wear and promoting slippage. Moreover, thermal degradation may also weaken any anti-slip coatings or laminates applied to the handle surface, directly impacting its performance. Recognizing this interrelationship is essential for developing comprehensive mitigation strategies.

To effectively address both Temperature Spikes and Handle Slippage, consider implementing the following measures:

These integrated strategies will help ensure that devices continue to operate safely and efficiently while reducing the likelihood of handle slippage.

Looking ahead, advancements in technology promise further improvements in managing Temperature Spikes and Handle Slippage:

Embracing these innovations will help manufacturers stay ahead of the challenges posed by thermal fluctuations and physical wear, ensuring long-term reliability and customer satisfaction.

Conclusion

Managing Temperature Spikes and Handle Slippage is vital for maintaining performance and safety in modern devices. By understanding the root causes, implementing targeted engineering solutions, and staying abreast of technological advances, manufacturers can effectively mitigate these issues. Continuous improvement, proactive maintenance, and smart design are the keys to enhancing product durability and ensuring a superior user experience.

Interested in learning how our advanced solutions can help you tackle thermal and grip challenges in your products? Contact us today for personalized strategies and expert insights.

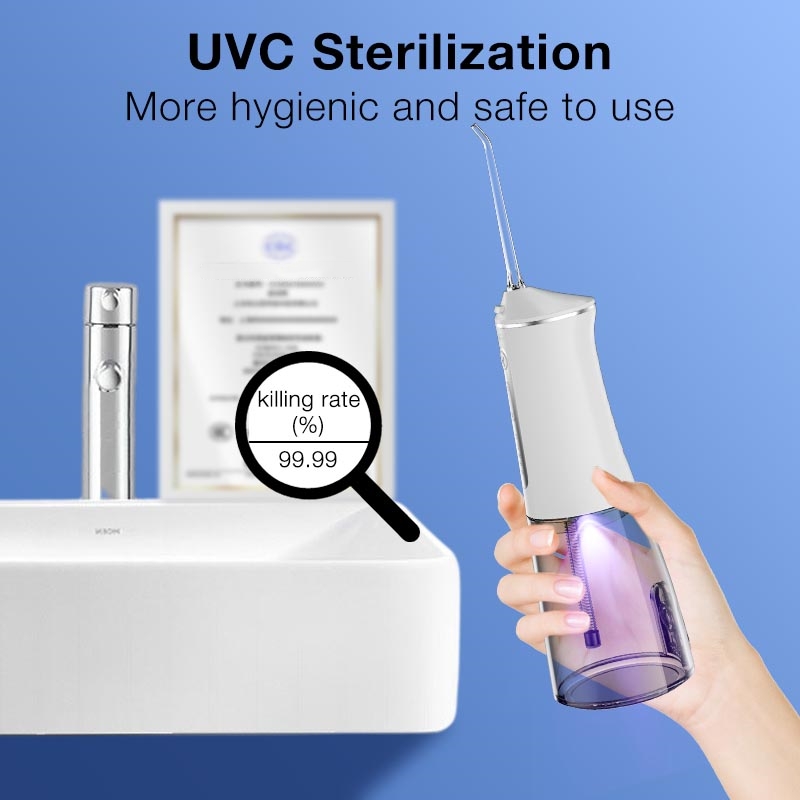

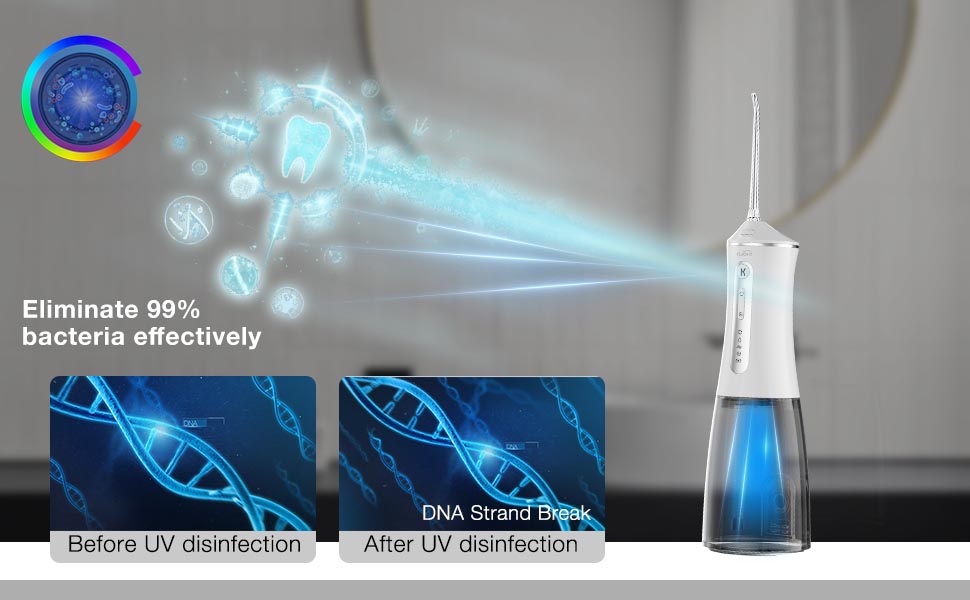

Preventing Mold in Water Flosser Tanks: Silver Ion vs. UV Sterilization

Travel Water Flosser Design: Power Compatibility, Storage & Waterproofing

The Workmanship of Electric Toothbrushes

Custom Your Electric Toothbrush or Water Flosser Brand Now!

Dentist’s Guide: Choosing the Right LED Whitening Device for Stains

Revolutionizing Oral Care: The Benefits and Effectiveness of Electric Toothbrushes

water Flosser Technology Innovation Leads to New Oral Care Trends

What are the advantages of ultraviolet sterilization water flosser?

Ways Having Whiter Teeth Can Help Boost Your Confidence

From manual to electric toothbrushes: a revolution in changing toothbrush habits

.jpg)

How to Clean Dirty Ports and Seal Deterioration?

Enjoy Using a Water Flosser to Boost Oral Hygiene

Can a Bangalore AI toothbrush boost your Efficient brushing tech routine?

Factors Affecting the Durability of Electric Toothbrushes

.jpg)

Smart Electric Toothbrush for Tech Professionals Koramangala

.jpg)

Is Your Electric Toothbrush Losing Power Too Fast?