As user expectations for high-precision oral care devices continue to rise, complaints involving sync disruption—particularly in sonic toothbrushes and high-frequency massaging tools—have become more than just performance issues. A new concern is emerging: lip sensitivity caused by seemingly minor inconsistencies in vibration, torque, or waveform synchronization. Could this pairing point to an overlooked design flaw? This article explores the mechanical-to-sensory link and outlines six key insights for manufacturers to avoid such unintended discomfort in end-users.

Sync disruption refers to the loss of alignment between internal motion components—such as motor oscillation, head rotation, or pulse modulation—and the intended control signal. In products like sonic toothbrushes, facial brushes, or lip-care massagers, synchronization is essential for delivering a uniform and gentle touch. Disruption can occur due to:

Even microsecond-level timing mismatches can create unstable pulses, which are especially perceptible in sensitive areas like the lips.

The lip area contains a dense concentration of nerve endings, making it one of the most touch-sensitive zones on the human body. When sync disruption causes irregular mechanical impulses, the resulting sensation can feel:

For users with pre-existing dryness, micro-cracks, or hypersensitivity, these irregularities may quickly escalate to discomfort or perceived irritation, even if the device meets general safety standards. Company web:https://www.powsmart.com/product/electric-toothbrush/

Design flaws that trigger sync disruption often stem from overlooked technical choices:

These issues might not show up in standard performance tests, but become apparent under real-time usage—especially in edge zones like lips or soft oral tissue.

From a B2B standpoint, recurring lip sensitivity complaints can result in:

Unlike more visible hardware failures, sensory design oversights are harder to quantify, making them even more critical to engineer out during early prototyping and validation.

To prevent sync disruption and its potential link to lip sensitivity, manufacturers should implement:

Integrating sensory-level testing into QA workflows bridges the gap between electrical specs and human perception.

The good news? Fixing sync disruption not only prevents discomfort but can become a strong product differentiator. By marketing precise, lip-safe operation and demonstrating validated sync stability, B2B manufacturers can:

What starts as a design flaw can evolve into a design feature—if addressed proactively and transparently.

Though often hidden beneath technical specifications, sync disruption and resulting lip sensitivity expose a fundamental gap between mechanical engineering and human-centered design. For forward-thinking manufacturers, this is not just a challenge—it’s a call to elevate vibration control and sensory testing as part of core R&D. Only then can we ensure that innovation not only performs—but feels right to the user. Contact us

.jpg)

.jpg)

.webp)

How Does Sonic Toothbrush Technology Integrate with a Smart Toothbrush App for Data-Driven Care?

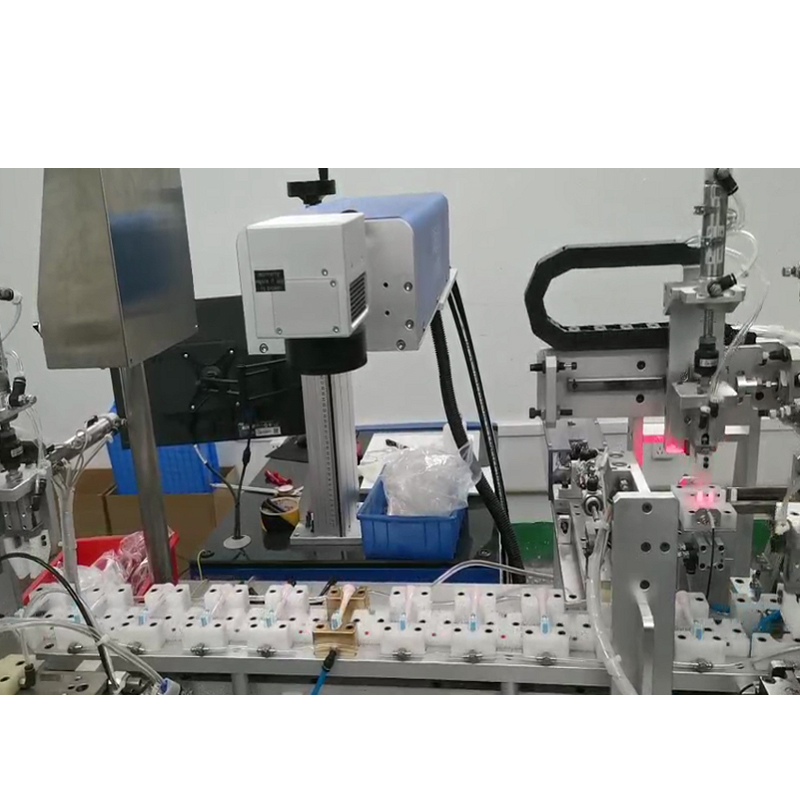

Electric Toothbrush Production Process Diagram: Complete Process from Injection Molding to Assembly and Key Points of Quality Inspection

How to Achieve a Win-Win Situation of “Consumption Upgrade” and “Cost Control”?

How Does Waterproof IPX7 Design Enhance the Durability of a Wireless Charging Base in B2B Oral Care Products?

How Do Quality Control Protocols Contribute to Rigorous Quality Assurance?

Solving the Common Issues of New Teeth Whitening Devices: Smart Countdown + How to Reduce 70% of Misoperations?

.jpg)

IPX7 waterproof electric toothbrush bulk

How does the orthodontic V-brush on this braces electric toothbrush clean behind wires?

.jpg)

LED Whitening Toothbrush OEM

.jpg)

LED Teeth Whitening Device Manufacturer for OEM & Private Label

What Are the Benefits of the Function That a Toothbrush or Water Flosser Gradually Starts Up in 3 Seconds?

Electric Toothbrush Industry Forecast for the Next 5 Years: Changes in Technology, Policy, and Consumption Scenarios

.jpg)

The Quietest Electric Toothbrushes.

Key factors in selecting water flossers

Frequency and Tips for Using Your At-Home Mouthpiece Recommended by Your Dentist

Do You Know How Much Damage a Rotating Electric Toothbrush Can Do to Your Teeth?