In the competitive personal care market, product reliability is non-negotiable. Yet one recurring issue threatens the performance and user experience of electric toothbrushes: motor vibration failure. When not properly controlled, unstable vibrations can lead directly to brush head detachment—a defect that frustrates users, inflates warranty claims, and risks damaging brand credibility. So, what’s really behind this issue, and how can manufacturers address it proactively?

The core of every electric toothbrush lies in its motor. If the motor generates inconsistent or excessive vibration, it creates strain at the connection point between the body and brush head. Over time, this leads to micro-loosening, wear of locking mechanisms, and ultimately brush head detachment during use.

Such detachment not only disrupts brushing but also poses a potential safety risk. Therefore, ensuring motor vibration stability is not just about performance—it’s about trust and user confidence.

Motor vibration failure can stem from several internal and external factors:

These issues often go unnoticed in early-stage testing but surface quickly once products reach users.

Manufacturers must identify early indicators that could point to potential motor vibration failure, such as:

Recognizing these signals early through rigorous testing can help avoid costly post-launch fixes.

Addressing motor vibration failure at the design stage is crucial. Several practical engineering strategies include:

Combining mechanical optimization with electronic control provides a more stable brushing experience—and reduces the risk of brush head detachment dramatically.

Even with stable motors, if the brush head interface materials are substandard, detachment can still occur. Key material considerations include:

These materials, coupled with precision tooling, ensure durability even under intense vibration.

Forward-looking manufacturers are leveraging accelerated lifecycle testing, finite element vibration simulation, and real-time usage data to identify and prevent motor vibration failure before products reach the market. These methods simulate months or years of wear in a matter of hours, revealing weak links that might otherwise be missed.

In addition, integrating smart diagnostics into the product’s firmware can provide early alerts to end-users—or even trigger automated service notifications—before a brush head detachment ever occurs.

The connection between motor vibration failure and brush head detachment is often underestimated but has significant implications for quality, brand perception, and safety. By understanding the root causes, investing in vibration control technologies, and engineering for durability, manufacturers can safeguard both performance and reputation.

In a market where consumers expect seamless performance, it’s not enough to build a brush that just works—it must work flawlessly over time. Ready to upgrade your product’s vibration resilience? Let’s talk about next-gen motor control and secure brush head architecture.https://www.powsmart.com/product/electric-toothbrush/

.jpg)

Ergonomic Handle Designs in Electric Toothbrushes: A Key Differentiator for Brands

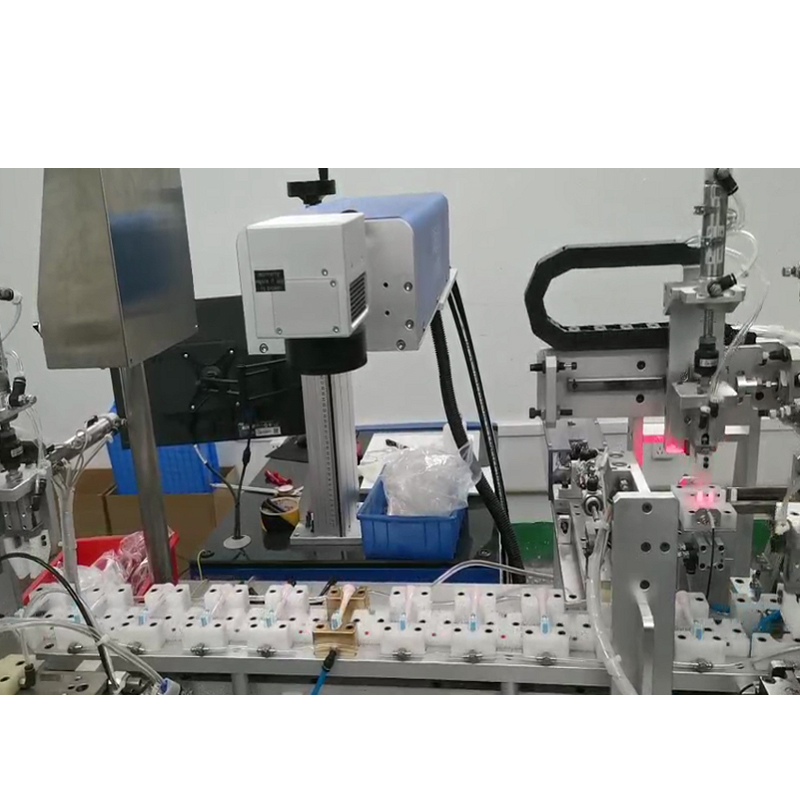

Electric Toothbrush Production Process Diagram: Complete Process from Injection Molding to Assembly and Key Points of Quality Inspection

Electric Toothbrush Battery Life: A Key OEM Consideration for Product Competitiveness

.jpg)

Excessive Noise With Pulp Inflammation? Dual Threats From Electric Brushes!

Why Adopt Latest Toothbrush Manufacturing Technology to Meet Toothbrush Production Standards?

Technological Innovation and Cost Control Strategies for Electric Toothbrush Factories

The Competitiveness of LED Teeth Whitening Kit

How Long to Charge a Water Flosser Before First Use? OEM Manufacturer’s Guide

.jpg)

How a Mumbai dental toothbrush enhances Periodontal care Mumbai standards

.jpg)

Customizable Sonic Toothbrush OEM – Personalized High-Performance Designs for Global Brands

What are the processes involved in making electric toothbrushes?

How Do I Know When My Toothbrush Is Fully Charged? OEM Solutions for Clear Indicators

.jpg)

Is Your POWSMART Smart Rechargeable Toothbrush Leaking Battery?

.jpg)

Budget Electric Toothbrush Under 1500 Rupees North Campus

Cost Structure Analysis and Risk Avoidance of Small Batch Trial Production for Whitening Teeth Devices

Is your sonic toothbrush Dallas equipped for the ultimate Dallas oral health defense?