In an increasingly saturated market, oral care brands are under pressure to stand out. Generic products no longer attract long-term customer loyalty. To increase brand core competitiveness, companies must create differentiated products that offer true innovation and added value. A key strategy for achieving this differentiation is to collaborate with factories with technological barriers—those that have advanced capabilities, unique R&D strengths, and manufacturing know-how that are difficult to replicate.

This blog provides actionable tips for oral care brands on how to identify the right manufacturing partners with strong oral care technological barriers to fuel brand innovation and market distinction.

Technological barriers refer to proprietary knowledge, advanced equipment, patented processes, or high-level R&D expertise that prevent easy replication by competitors. In the context of oral care manufacturing, this might include:

High-frequency motor design for electric toothbrushes

Precision injection molding for ergonomic brush heads

Ultra-fine nozzle engineering for water flossers

Smart sensor integration and mobile app ecosystems

Sustainable material development and biocompatibility testing

Partnering with factories with technological barriers gives brands access to these cutting-edge capabilities, enabling them to launch premium, innovative, and high-performing oral care products.

Choosing the right factory isn’t just about price—it’s about potential. Here’s how factories with technological barriers help create differentiated products:

Faster innovation cycles: Their in-house engineering teams can rapidly turn new concepts into functional prototypes.

Product exclusivity: Some manufacturers offer exclusive technology licensing or co-development, helping you protect your design from duplication.

Quality consistency: Their technological know-how translates to more reliable and consistent production processes.

Regulatory expertise: These factories often meet stringent global certifications (e.g. FDA, CE, ISO13485), critical for brands expanding internationally.

Such capabilities help your brand move away from commoditized products and toward category leadership.

Here are practical tips for oral care brands looking to find a high-tech manufacturing partner:

Evaluate Patents and Certifications: Check if the factory holds any patents or has experience with certified production standards.

Request Process Transparency: Ask for details about tooling, automation, software development, and post-processing techniques.

Look for Integrated R&D: Factories with in-house R&D teams can better support custom development.

Assess Their Client Portfolio: Working with top-tier or international brands is usually a positive sign.

Visit the Factory: On-site audits reveal not only their technology level but also management quality and scalability.

A thoughtful partner selection process is key to aligning with factories that bring genuine oral care technological barriers to the table.

To illustrate, consider the following cases:

A European oral care brand partnered with a factory specializing in micro-vibration motor tech, creating a toothbrush with patented noise-reduction and pressure feedback—products that quickly positioned them as premium in a crowded market.

A U.S. brand used a Chinese factory’s proprietary water jet system to co-develop an irrigator with dual-pulse modes—leading to a successful retail launch with a unique product story.

These cases highlight how factories with technological barriers help increase brand core competitiveness and shorten the path to innovation.

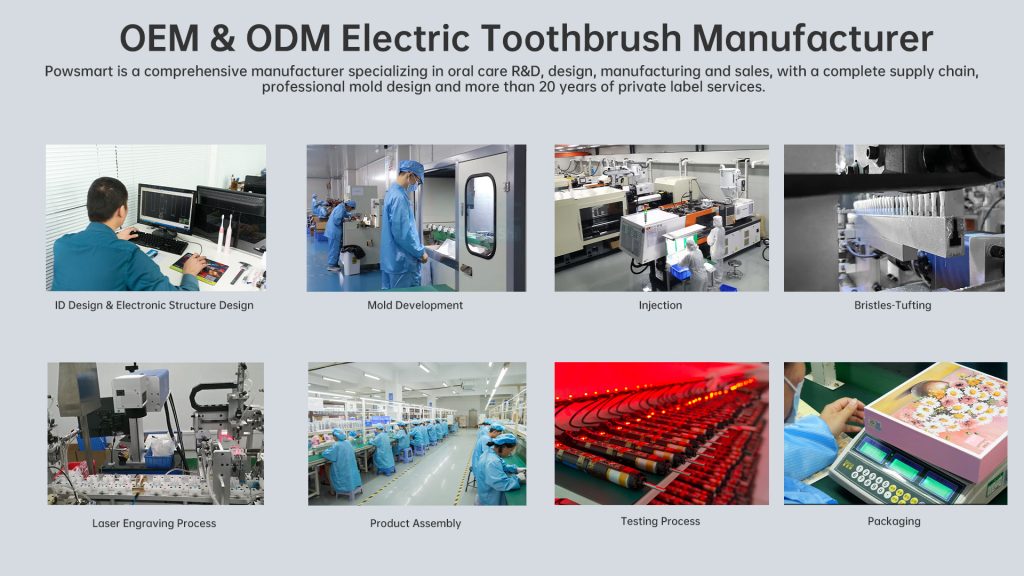

In a competitive and evolving oral care market, innovation is not optional—it’s essential. Partnering with factories with technological barriers enables your brand to create differentiated products that can’t easily be copied. This is the most strategic way to increase brand core competitiveness and build lasting customer loyalty. Powsmart not only meet your current needs but also grow with you in the future. Contact us if you wanna have a further talk. https://www.powsmart.com/product/electric-toothbrush/

What is the Market Outlook for Supplying Electric Toothbrushes to Hotels & Hospitals?

Choosing Between Salt Water and Hydrogen Peroxide for OEM Gum Care Products

Is the Manufacturing Process of Electric Toothbrushes Complicated?

Cracked a crown? Tacoma repair services for dental crowns — fast?

.jpg)

How to Use Electric Toothbrush First Time Guide Hindi

New Trends in the Electric Toothbrush Industry: How Can Intelligent Connectivity Enable Brand Premium?

.jpg)

Electric Toothbrush Design Customization for OEM and Private Label Brands

.jpg)

Is There a Promising Future for the Beauty Equipment Brand to Expand into Oral Care Products?

Custom Toothbrush Handle Designs – Texas OEM Manufacturing Capabilities

How to Avoid Infringement Issues When Developing a Private Brand Electric Toothbrush

Can a California whitening brush protect California sensitive teeth?

.jpg)

Water Flosser Sterilization Function: UV Sterilization vs. Silver Ion Coating – Real Cost and Effect

.jpg)

Teeth Whitening Device Compliance in the EU Market: A Guide for OEM Buyers

Are Electric Toothbrushes a Good Investment?

How Can I Disinfect Electric Toothbrush Head? BPA-Free & Hygienic Options

High After-Sales Costs: How They Cripple Oral Care Brand Profits & Reputation